Biodegradable means the total breakdown of a product (by microorganisms) to something found in nature.

What is Biodegradation of Plastic? How is it done using BioSphere’s Product?

Making your product biodegradable is what BioSphere Plastic has invested their time and energy on perfecting over many years studying and inventing their biodegradable options for the marketplace. You will find answers to your tough questions below on how plastics are biodegradable and how we enhance these characteristics in your plastic products.

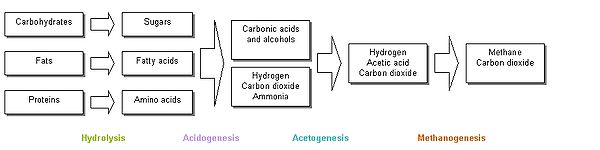

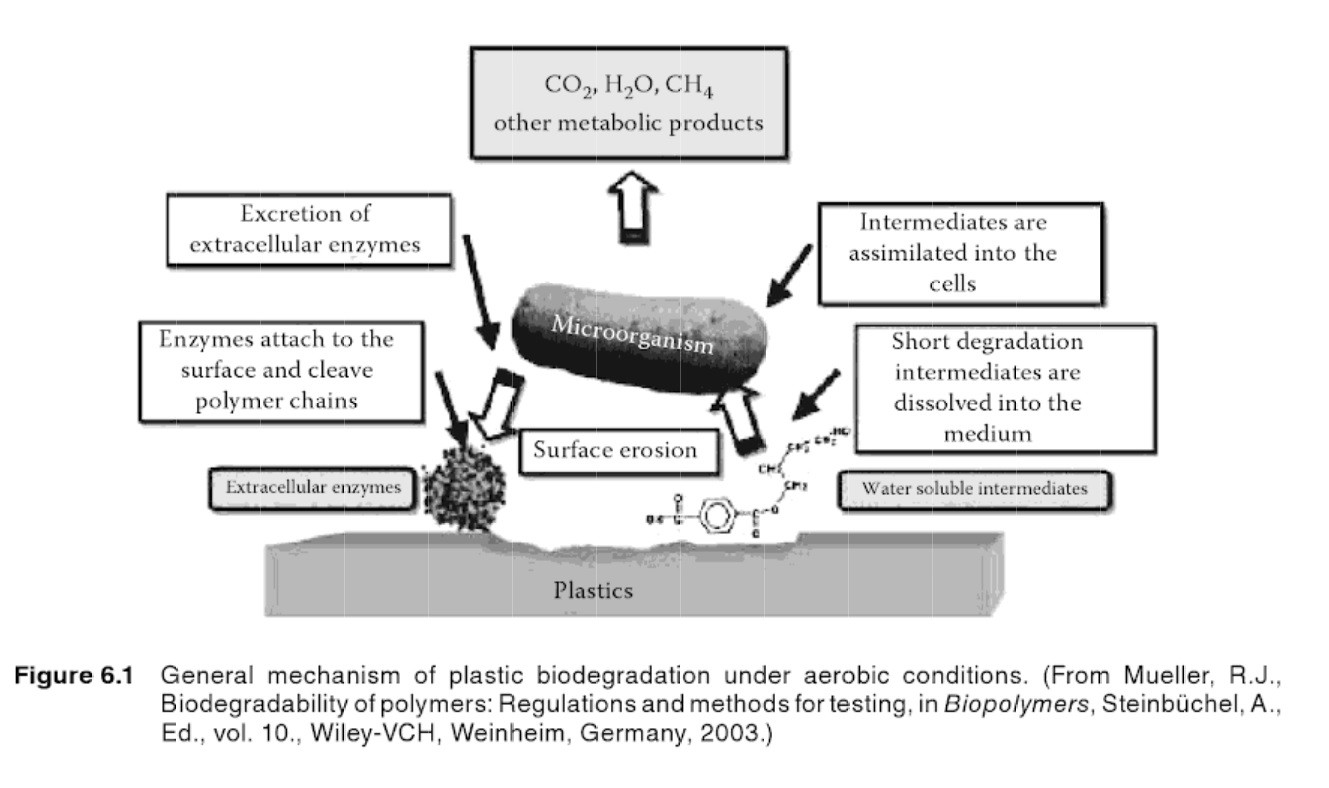

In most cases, plastic is made up of hydrophobic polymers. Chains must be broken down into constituent parts for the energy potential to be used by microorganisms. These constituent parts, or monomers, are readily available to other bacteria. The process of breaking these chains and dissolving the smaller molecules into solution is called hydrolysis or oxidation. Therefore, hydrolysis(using water) or oxidation(using air) of these high-molecular-weight polymeric components is the necessary first step in anaerobic or aerobic biodegradation. Through hydrolysis or oxidation or a combination thereof, the polymers are converted from long chains to simple monomers and further into carbon dioxide(Aerobically), methane gas(Anaerobically), water and metabolic biomass.

The biodegradation of large polymers to carbon dioxide, water, and metabolic products requires several different organisms, few microbes consume the polymer chain and break it down to its simpler monomer, while others use the monomer consuming it both intercellularly and extracellularly further converting to by-products – CO2, water and metabolic products, biomass rendering the product biodegradable.

During the process of which plastic becomes biodegradable, the exoenzymes from microorganisms turn the long polymer chains into shorter chains yielding oligomers, dimers, monomers passing through the bacterial membranes and utilized as carbon. It is important to understand that plastic will never reach 100% off-gassing(testing by respiration only tests the CO2 or CH4 off-gassing) when testing, as some of the product gets incorporated into microbial biomass, humus, and other natural products(Atlas and Bartha, 1997; Narayan 1993)

The below photo shows how basic plastic is biodegradable

How BioSphere is a Game Changer

Biosphere has dedicated many years in developing an additive which is cost affordable and enhances the biodegradation of plastic articles at rates never before seen in the industry. Many are calling it a game changer or a baseline in the world of plastics. In the majority of testing which has been conducted over half a decade on plastic, no organization has seen anything close to the results which are produced using the biodegradable additive technology produced by BioSphere. The testing which was conducted by ISO testing methods and the ASTM D5511, 5526 and 7475 testing methods for Anaerobic biodegradation show biodegradation of almost all polymers including LDPE and other olefins at a baseline minimum of 60% in a year. Contact us for more information on making your final product decompose using one of our additives, or make a custom product just for your organization tailoring it to your biodegradation needs.